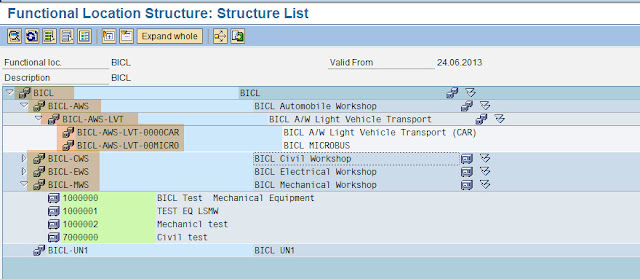

A PM Functional Location represents the system area where an object can be

installed. The objects that can be installed at functional locations are

called pieces of Equipment in SAP.

Eg. BICL-MWS = BICL Mechanical Workshop is a Functional Location, where

several objects (Equipments) Like Shape Machine, Lathe Machine, Drill

Machine can be installed.

Purpose of Functional Location:

* Equipment installation and monitoring.

* Execution of maintenance tasks.

* Recording of maintenance tasks.

* Data collection over long periods of time.

* Cost monitoring by area.

Criteria of Functional Location :

You should use functional locations to structure your systems if:

-You want to represent the structures of the technical systems in your company

according to functional criteria.

-Maintenance tasks have to be performed for the individual parts of your technical

system and this work must or should be recorded.

-Technical data for certain parts of your technical system has to be collected and

evaluated over a longer period of time.

-The costs of maintenance tasks have to be monitored for certain parts of your

technical system.

-You want to perform analyses regarding the influence of usage conditions on

damage susceptibility for the pieces of equipment installed.

T Code :

IL01 = Create

IL02 = Update

IL03 = Display

--------------------------------

IH01 = Structural Display

Criteria of Functional Location :

You should use functional locations to structure your systems if:

-You want to represent the structures of the technical systems in your company

according to functional criteria.

-Maintenance tasks have to be performed for the individual parts of your technical

system and this work must or should be recorded.

-Technical data for certain parts of your technical system has to be collected and

evaluated over a longer period of time.

-The costs of maintenance tasks have to be monitored for certain parts of your

technical system.

-You want to perform analyses regarding the influence of usage conditions on

damage susceptibility for the pieces of equipment installed.

T Code :

IL01 = Create

IL02 = Update

IL03 = Display

--------------------------------

IH01 = Structural Display