Overview :

Documenting

the condition of a particular object (Equipment) is of great importance in

cases where detailed

records regarding the correct condition have to be kept for legal reasons. This

could Involve

critical values recorded for Machine or environmental protection purposes, hazardous

working areas

that are monitored for health and safety reasons, the condition of equipment in hospitals

(intensive care units), as well as measurements of emissions and pollution for objects of all types

In SAP System Measuring points describe the physical locations

at which a condition is described , ( For example, Temperature, Pressure

on a Boiler, Dash Board or Odometer of a Vehicle The characteristics associated with the measuring points

which record the value can only be numeric characteristic.

Measuring points are located on technical objects, in other words, on pieces of equipment or functional locations. For every measuring point there should be some characteristics to measure the reading.

Purpose :

For better monitoring of capacity utilization, maintenance objects have measuring points and counters to record flow quantities or operating hours, for instance. Measurement and counter readings are stored in the system in the form of measurement documents. These documents are the basis for performance-based maintenance planning.

Counter :

Counter is

type of measuring point, where a continuous reading is recorded (e.g. Kilometer, Hour Meter). Counter

readings are taken at counters at particular intervals and in particular

measurement units.

The above Picture given (Kilometer) is treat as a counter where Kilometer reading we can take from certain intervals.

Characteristics and Class :

Characteristics : Specification or Quality belonging to a Technical Object ( Equipment, Functional Location )Characteristics are used to store additional data or condition value.

Class : A Class is a collection of Characteristics. Class is assign to Equipment or Functional Location

Step 1 : Create Characteristics ( T Code : CT04)

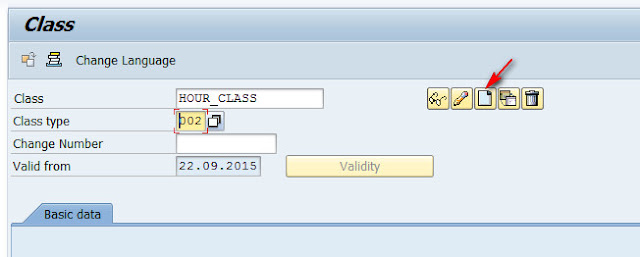

Step 2 : Create Class ( T Code : CL02)

Step 3 : Assign Class to Equipment

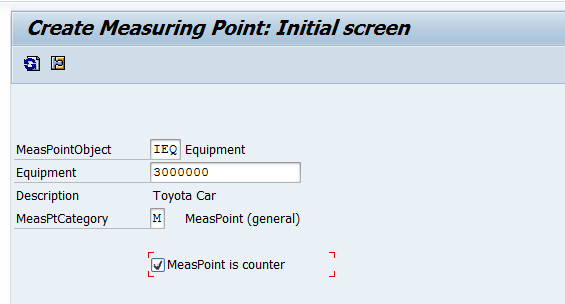

Step 4 : Create Measuring Point - IK01 (Counter Base)

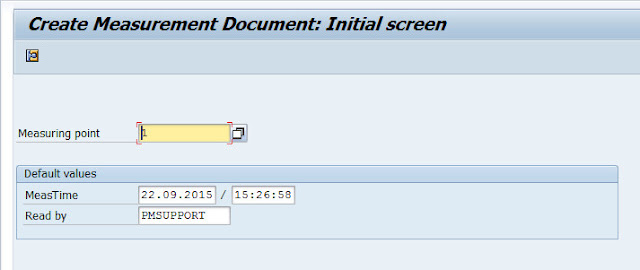

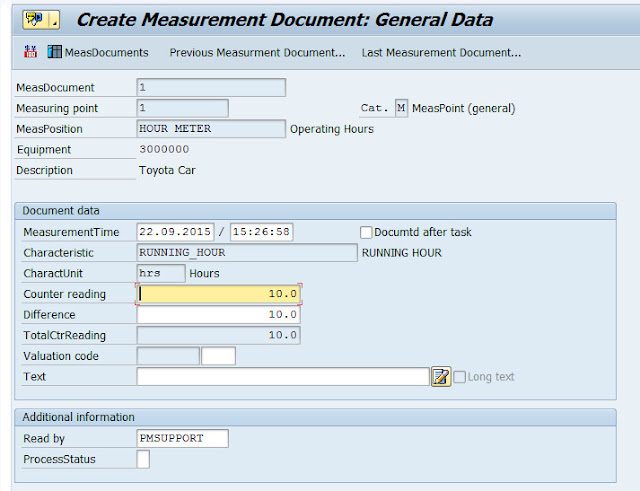

Step 5 : Create Measurement Document ( T Code : IK11)

Enter

Save

Step 6 :Measurement Document List : IK17

Configuration :

Define measuring points category

IMG>Plant maintenance & customers services>Master data in plant maintenance & customers services>Basic setting>Measuring point counter & measuring documents>Define measuring point category.

Click on new entry and create new measuring point category if required

Create no of ranges for measuring point

IMG>Plant maintenance & customers services>Master data in plant maintenance & customers services>Basic setting>Measuring point counter & measuring documents>Create no ranges for measuring point.

Click on intervals & create no ranges

Create no of ranges for measuring Documents

IMG>Plant maintenance & customers services>Master data in plant maintenance & customers services>Basic setting>Measuring point counter & measuring documents>Create no ranges for measuring documents

Define field selection for measuring point & measuring Documents

IMG>Plant maintenance & customers services>Master data in plant maintenance & customers services>Basic setting>Measuring point counter & measuring documents>Define field selection for measuring point & measuring Documents (T Code : OIMRC)

END

thank you! veru nicely explained.

ReplyDeleteIf you are looking for a way to improve your CMMS and maintenance management via SAP, you can connect it to Mobility Work CMMS

ReplyDeleteReally good document. Can you please publish counter base maintenance plan process

DeleteInteresting Content Thanks For Sharing.

ReplyDeletePlease do visit the link below.

customized inventory software services in bangaore

Very Nice Explanation with examples on the Measurement Points and Documents. Keep up the good work and help people like me in learning

ReplyDeleteReally insightful! Thanks for breaking this down.

ReplyDeleteAdobe Photoshop Download

SuperAntiSpyWare Pro

PC Helpsoft Driver"